Considering the usage rates that we were seeing from Centor, I approached Markforged and Centor to see if they would like to write a case study and they were happy to oblige.

Case Study: Functional Rapid Prototyping

Challenge

To validate components and assembly designs that had high machining costs and unreliable outsourcing results.

Solution

Consistently high-quality, robust 3D printed parts to provide a more efficient method of producing functional prototypes.

Results

Lightening-fast iterations on product designs and validation checks of form, fit and basic function by 3D printing prototypes in-house.

Background

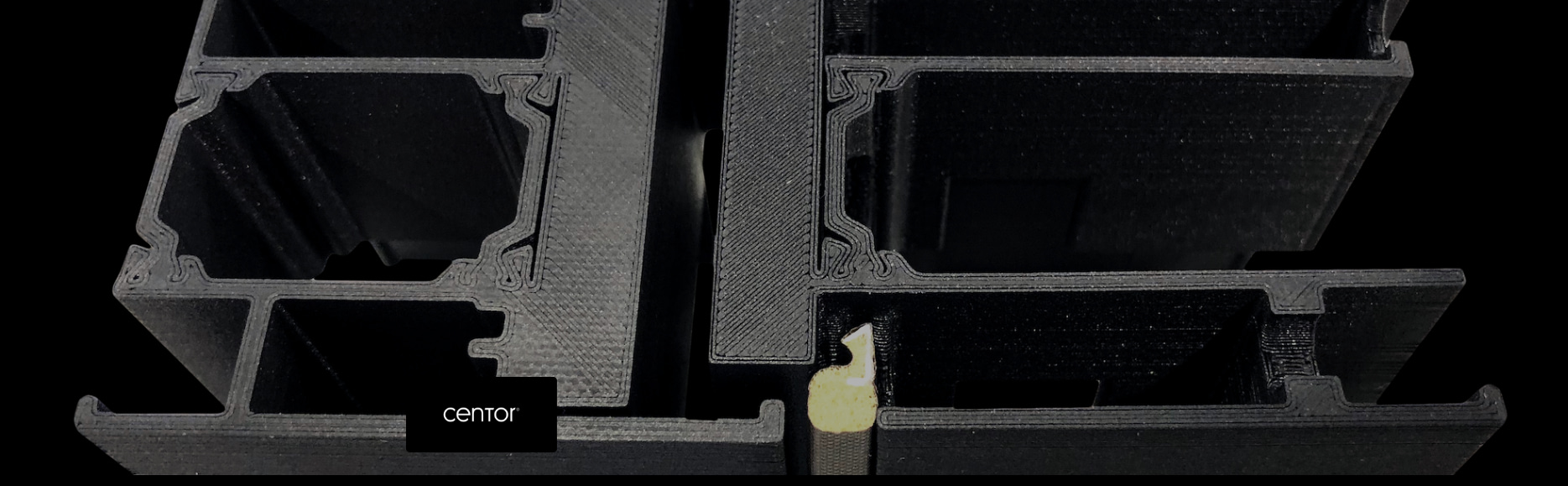

Centor has a marvellous product range, including custom integrated doors for residential and commercial buildings. Every unique design requires a proof of concept to be built. Three in-house machinists used to spend all their time fabricating components in low volumes, with additional components being outsourced. This approach led to inconsistent quality, lengthy production times, and excess costs. Seeking an alternative, Group Manager of Product and Engineering David Chappell took a chance on Markforged and was immediately impressed: “It’s the first time I’ve ever actually seen a 3D printer do what it promised in a real-life design studio factory like ours. It just runs.”

While his team of experienced manufacturers initially expressed doubt about integrating 3D printing in their workflow, they now run the printer almost 24/7. It enabled them to redirect machining bandwidth, iterate on designs, learn quickly from printed parts, and present compelling proofs of concepts to customers. This in-house efficiency “takes out one blockage to innovation”. Centor further optimised their production by printing jigs and weatherproof end-use parts. They will soon have a Markforged printer in each of their four factories across Australia, China, Poland, and the US.

Benefits

- Form and Function

Tight tolerances ensure that multiple components fit together perfectly and enable the prototype folding doors to function reliably. - Production On Demand

Markforged’s cloud software allows Centor to easily translate their CAD designs into printed parts, with accurate time and cost estimates. - Complex Geometries

Free from the constraints of subtractive machining, 3D printed parts can be designed with complex geometries that improve product function.